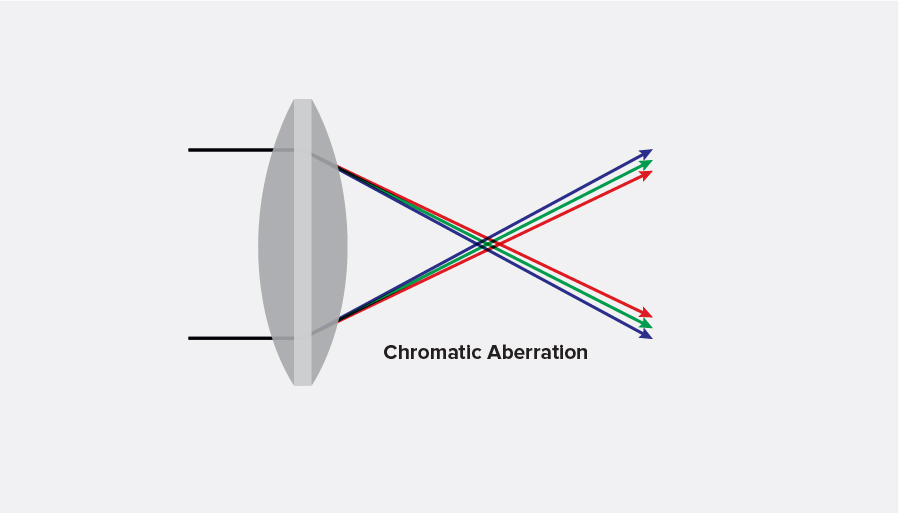

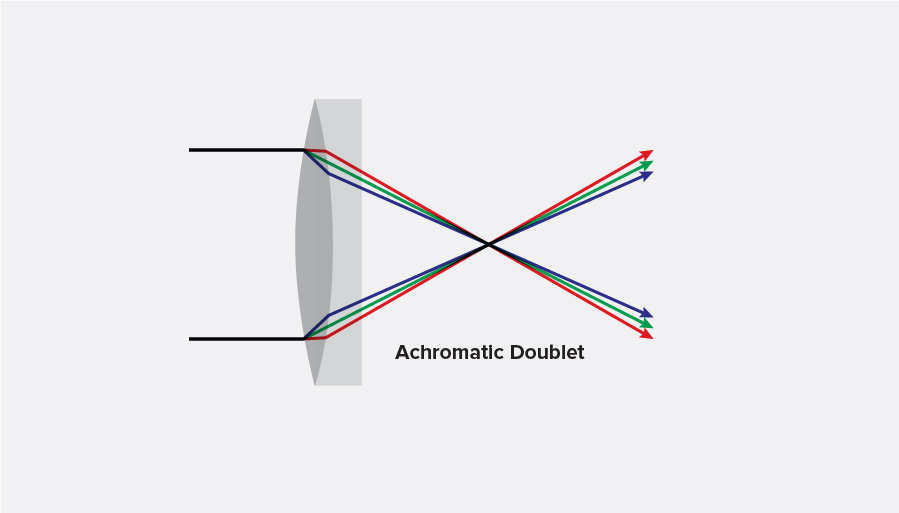

A compound lens, also mentioned as an achromat, typically consists of two optical components cemented together, usually a positive low-index (crown) element and a negative high-index (flint) element. as compared to a single lens, or singlet for brief, which only consists of one piece of glass, the extra design freedom provided by employing a doublet design allows for further optimization of performance. Therefore, a compound lens will have noticeable advantages over a comparable diameter and focal distance singlet.

A compound lens comes during a sort of configuration, most notably, positive, negative, triplet, and aspherized. it's important to notice that it is often a doublet (two elements) or triplet (three elements); the number of elements isn't associated with the number of rays that it corrects. In other words, a compound lens designed for visible wavelengths corrects for red and blue, independent of it being a doublet or triplet configuration.

The process of creating achromatic lenses starts with a quote generated by a Manufacturing Engineer. The right optical glass material is then ordered and sent to the production line. While in production, the crown and flint lenses are manufactured separately in a typical fashion. The crown is convex and is made using lower-dispersion material while the flint is typically concave and utilizes relatively higher dispersion material. Once we manufacture the various lenses, they are aligned in both the optical and mechanical axis and cemented together using a specialized index-specific optical cement. The optical cement is then cured using UV light. After assembly, some of the doublets are centered to the final diameter while others are pre-centered before cementing. Doublets can also be blackened after assembly to reduce scattering, which can be beneficial in some optical applications.

Aspherical achromatic lenses contain two cemented elements, a positive low-index crown glass lens element cemented to a negative high-index optical flint lens element. These elements are carefully selected to cancel aberration at two well-separated wavelengths; which give superior color correction and thus the littlest RMS spot size closest to the diffraction limit.

The second element of the lens is aspherical to reduce wavefront errors arising from standard spherical achromats. These aspherical achromatic lenses are the perfect choice for imaging, fiber coupling, scanning, and other applications that use broadband laser or white light sources.

Achromatic aspheres utilize a broadband visible coating on the front side to supply optimal transmission. The antireflection coating is applied to the front surface, whereas the rear surface features a molded aspheric polymer cap with a protective seal.

These lenses are often used within the wavelength regime of 400-2000nm. However, the colour and aberration correction is merely optimized over the wavelength regime of 400-700nm. The Aspherical achromatic lenses not only have superior color correction compared to plain achromats, but even have very similar aberration corrections to those of machined aspheres.

Name: Sales Department

Mobile:+8613019214973

Tel:86-431-81905988

Whatsapp:+8618043023344

Email:info@csopt.com

Add:No.3 Shenzhen street, Economic and Technology Development Zone ,Changchun China

We chat